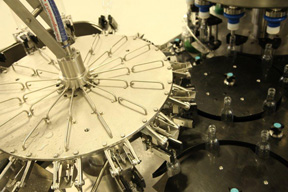

RFC SERIES - RINSER FILLER CAPPER

The RFC Series of monobloc rotary rinsing, filling and capping machines is the result of over 15 years of activity in the field of liquid filling. The RFC Series is supplied in two versions: The RFC-P series is for pharmaceutical applications and the RFC-G Series is for food, beverage, cosmetic, personal care and home care applications.

The RFC Series is modular and flexible, offering the pharmaceutical, food, beverage, cosmetic, personal care and home care industries the right technological filling solutions.

The RFC-P and the RFC-G series are offered as a Monobloc Rinser Filler Capper. With a high degree of flexibility and modularity, this machine series allows compact and effective combinations to satisfy even the most stringent filling requirements.

Filtec Automation offers a range of Rotary Rinser Filler Cappers, to fill free flow low viscosity products such as milk, water, beverages, cordials and spirits to higher viscosity products such as creams and lotions. The Rinser Filler cappers can handle a large range of glass and plastic bottles from 50ml to 5L with outputs up to 250 bpm.

Filtec Automation offers a range of Rotary Rinser Filler Cappers, to fill free flow low viscosity products such as milk, water, beverages, cordials and spirits to higher viscosity products such as creams and lotions. The Rinser Filler cappers can handle a large range of glass and plastic bottles from 50ml to 5L with outputs up to 250 bpm.

The Rinser turrets are offered from single stage to multi-stage rinsing. Options such as Ozonated water rinsing, air rinsing etc are available.

The Filling principle is extremely simple with an in feed scroll and star wheel moving containers into the rinsing turret. The rinser inverts the container and then injects a high pressure jet of water into the bottle for a controlled period of time. The bottle is then allowed to drip before being re inverted and transferred to the filling turret.

The RFC series machines are offered in both Level Fillers for low viscosity products and Flow Meter Fillers for higher viscosity products.

Level Filler option: Level filling turrets are used for low viscosity liquids only. The containers are lifted on a cam, thus opening the level nozzles with filling automatically stopping at the required fill height. The fill height is simply adjusted by adding or removing spacer rings from the nozzles.

Flow meter filler option: RFC fillers equipped with flow meter filling turrets are ideal for a variety of products such as syrups, solutions, suspensions or oils, creams and lotions with medium viscosity. Mass and Mag flow meter options are available with single and dual speed filling nozzles for improved filling speed and accuracy. Bottom up filling nozzles are also available for foaming products. Flow meter fillers offer many advantages over older technologies and these include minimal maintenance, accurate filling, fast and effective CIP, flexibility.

The RFC series of machines is very compact and ergonomic and couples Rinsing and level filler or flow meter filling technology with capping station. The capping turrets can be equipped for all types of closures such as screw caps, push on caps, aluminium ROPP caps and all types of Pharmaceutical caps.

Thanks to the high level of integration and to the proven reliability of the individual machines the Filtec lines provide high output for the entire production process.

Filtec offers the food, beverage, home care, pharmaceutical and cosmetic industry state-of-the-art machines and we strive towards new innovations by constantly developing and upgrading our filling technology.

Combining essential features and the simplicity of proven closing systems with widely appreciated high standards of quality and reliability, the RFC Series of high speed level and flow meter fillers is the ultimate innovation in the Filtec filling range. The particularly versatile RFC Series has been designed to reach an output speed of up to 250bpm with up to 36 filling heads and 10 capping heads.

Our high speed machines can be equipped with the latest generation of completely automated CIP-SIP systems.

Filtec has developed an automated CIP/ SIP system for it’s RFC Series of Rotary Fillers, which remarkably reduces the manual intervention of the operator with subsequent saving on time and money.

All manual operations between the CIP and the SIP phase have been eliminated and are carried out automatically. The flexible pipes for the washing media and for the steam are now easily connected one to the other and to the fluids discharge manifold, by means of quick-couplers. This system avoids any spillages or leaks of liquid during the entire cleaning process.

All of our RFC Series machines are fully validated and can be supplied with validation documentation.

Automatic adjustment of the filling and capping turret height is done by means of motors.